The George Woodruff School of Mechanical Engineering

Office: IPST 550-A

Email: kai.yu at gatech.edu

Education:

BS: Harbin Institute of Technology, China, 2008

Research:

I joined Dr. Qi’s group in January, 2011. My research focuses on 1) thermoviscoelastic modeling of shape memory polymers; 2) reprocessable and recyclable thermoset polymers.

Shape memory polymers (SMPs) are at the forefront of recent material research. Although the basic concept of SMPs has been known for decades, recent advances in SMP research demonstrated many interesting properties that have not been touched before. For example, the programming temperature can significantly affect the free recovery behavior for SMPs under the same recovery conditions, namely the programing temperature memory effect. Also, when properly programmed, multi-shape memory effect will be observed if we use stepped heating manner for free recovery.

In my research work, a multi-branched constitutive model is applied to predict the complicated dependency of the SM performance on thermo-temporal conditions in an SM cycle, as well as analyze the energy releasing mechanism within the polymer system. We also demonstrated that the influence of programming conditions to the free recovery can be unified by a reduced programming time that uniquely determines shape fixity, which consequently uniquely determines the shape recovery with a reduced recovery time. As seen in the following shape memory performance map (SMP-map), when predict the polymer shape fixity, the only thing we need to do is calculating the reduced programming time according to the thermal history. For the free recovery, after calculating the reduced free recovery time based on the recovery condition, we can predict recovery ratio in combining with the pre-determined shape fixity. A detailed procedure on how to use the constructed SMP-map can be found on here.

Reprocessing and recycling of thermosetting polymers is inherently difficult for traditional technology because of their chemically cross-linked nature. Disposal of such polymer wastes typically requires landfills, or high temperature or toxic chemicals, which lead to significant environmental concerns. By introducing exchangeable bonds into the polymer system, the cross-linked thermoset can rearrange their microscopic topology at high temperatures without impairing the network integrity. This new technology will enable a malleable, reparable, recyclable and yet insoluble thermoset network, and also save many problems for environmental protection.

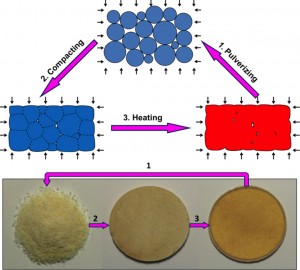

The following figure shows a typical recycling routine in my study. When heat is applied, the pulverized polymer can be welded on the interfaces and tends to be a compacted and consolidated form. Further heating renders an essentially complete welding effect where the sample appears transparent and resembles the fresh sample. This process can be repeated several times in manufacturing complex objectives. My research works involve characterizing the mechanical properties of the recycled thermoset polymers, as well as constitutive modeling of interface behavior during the welding process.